CNC Machining, Custom Fabrication, Engineering, and More

From RFQ to Parts Fast

40+ years of industry experience

Prototype to production manufacturing, 3D printing, and finishing in one shop

Quote responses in 24 hours or less

Avoid machining mistakes, misfits, and delays that can cost thousands. Get a competitive quote from a shop that engineers your parts right the first time.

OUR SERVICES

Dream it

With decades of expertise in engineering, physics, and design, we provide specialized services that accelerate product development and optimize process automation, including:

CAD (Computer-Aided Design) for precise 3D modeling and prototype development

CFD (Computational Fluid Dynamics) to analyze and optimize fluid flow and thermal performance

FEA (Finite Element Analysis) for validating structural integrity and stress response

Reverse engineering to reproduce or enhance existing components and assemblies

High-quality product mockups, photorealistic rendering, and technical visualization using Adobe Creative Suite

Custom automation design and system integration to improve process control, efficiency, and scalability

Industrial electrical engineering including control panel design, PLC programming, wiring, and troubleshooting

Process optimization focused on reducing cycle times, minimizing waste, and increasing throughput

No project is too small or complex. Our team delivers end-to-end solutions that drive innovation and operational excellence from concept through deployment.

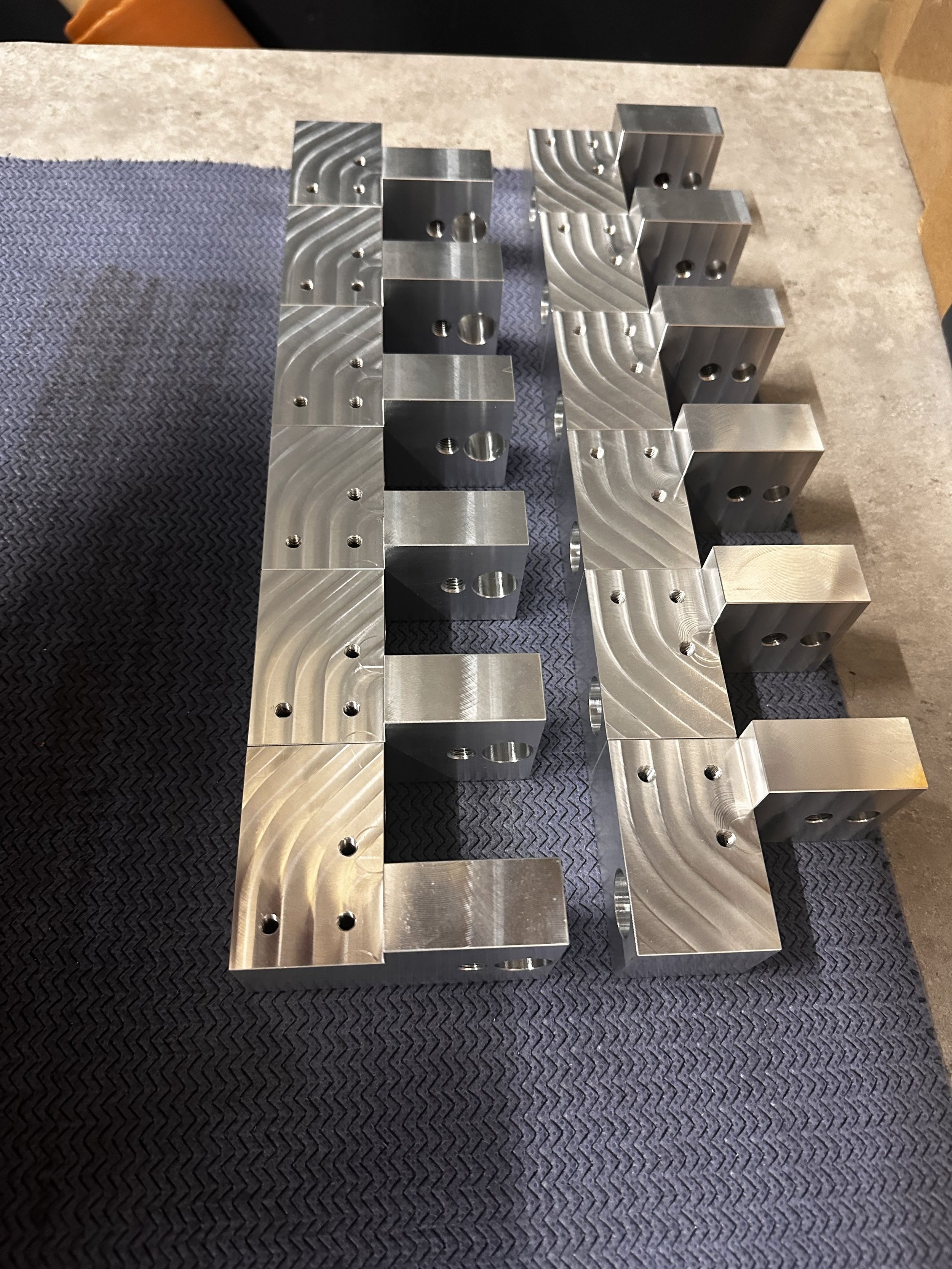

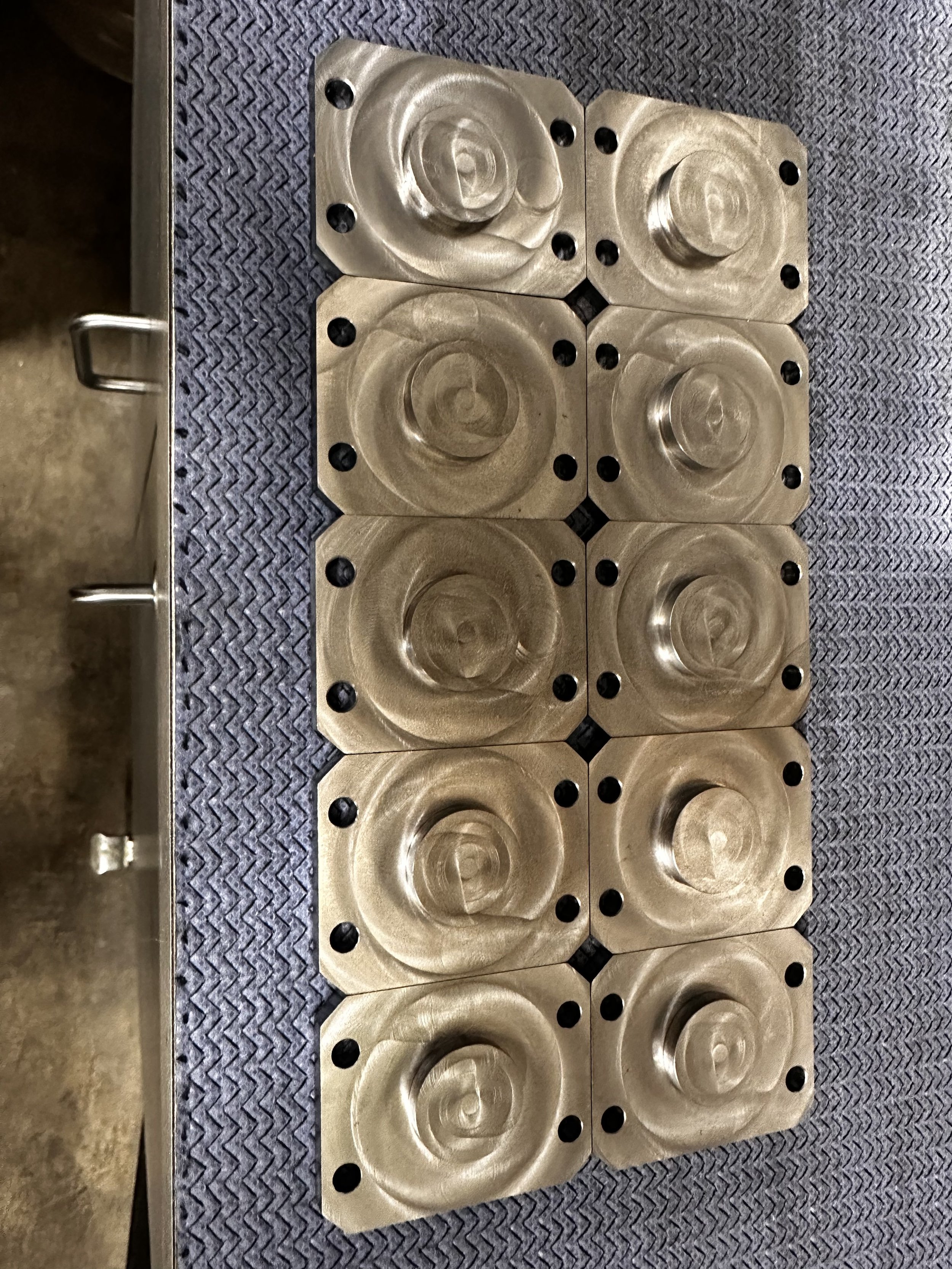

Cut it

With years of experience in precision machining, we offer advanced capabilities to meet a wide range of manufacturing needs, including:

Turning: High-precision CNC turning for round parts, shafts, and features with tight dimensional control

3-axis milling: Ideal for complex parts with accurate flat and contoured surfaces

4-axis milling: Enables rotary positioning for enhanced geometry flexibility

5-axis milling: Allows simultaneous multi-axis movement for intricate, high-tolerance components

Mill-turn machining: Combines milling and turning in a single setup for greater efficiency

CNC cylindrical grinding: Provides precise surface finishing for cylindrical parts

Tool grinding: Sharpens and forms cutting tools to exact specifications

We routinely achieve surface finishes better than 15 µin Ra, delivering the precision and quality required for demanding applications. From single custom parts to large production runs, our state-of-the-art equipment and skilled machinists ensure consistent, high-performance results.

Our value stems from decades of engineering and design experience, enabling fast design cycles, efficient manufacturing methods, and custom fixturing that reduce cost and increase throughput without compromising quality.

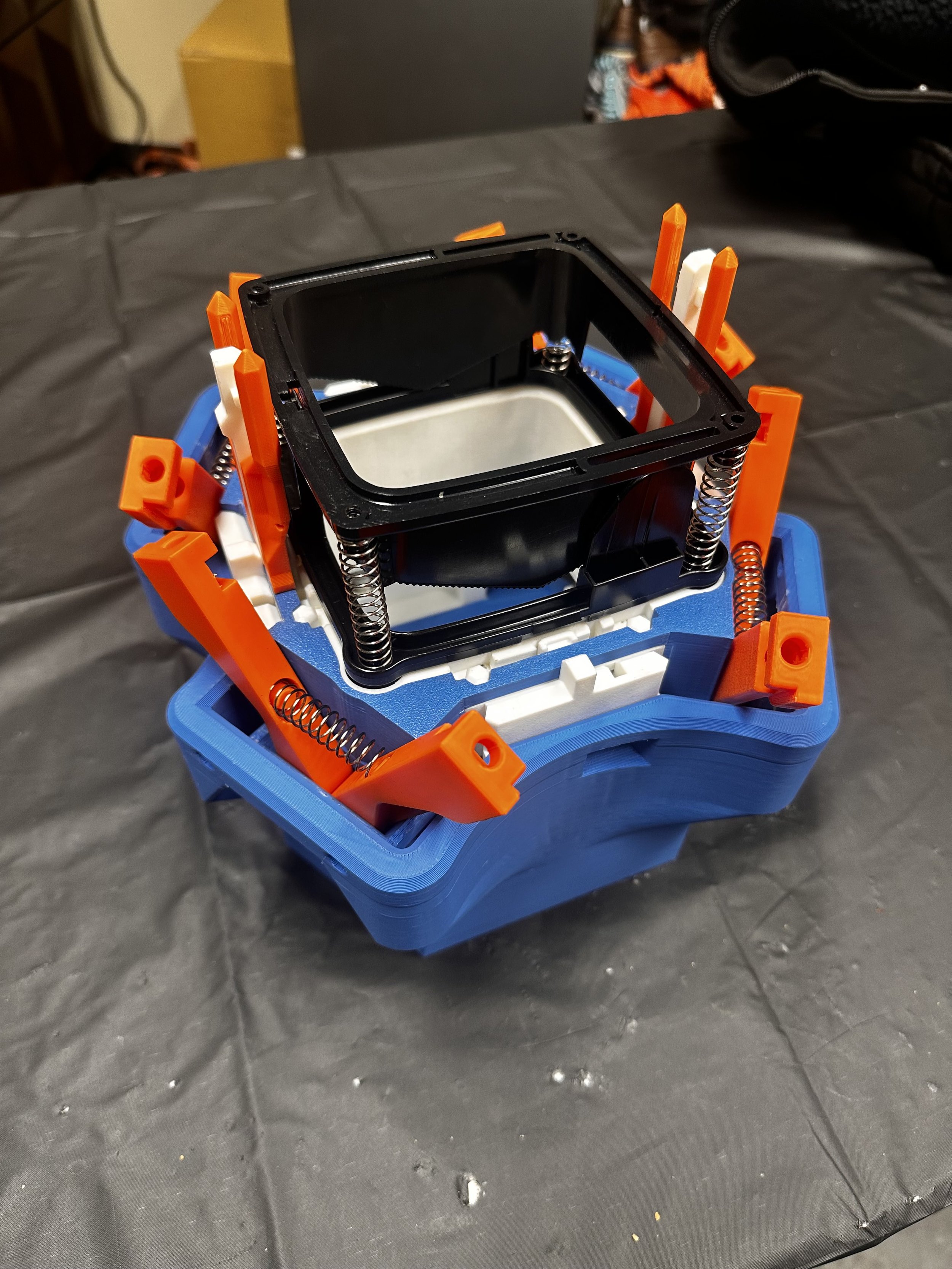

Print it

We provide comprehensive FDM 3D printing services to support everything from rapid prototyping and functional models to full-scale production. Whether you need a one-off part or a large batch run, our advanced printer fleet ensures consistent quality and fast turnaround times.

We work with a wide range of materials tailored to diverse application needs, including:

PLA - low cost, ideal for low-temperature use; biodegradable in certain environments

ABS - impact resistant, good for stressed parts; handles higher temperatures than PLA

PETG - strong, food safe, and moderately flexible

Nylon - chemically resistant, high-strength, high-temperature, and UV resistant

Carbon Fiber Reinforced Filaments — increased stiffness, tensile strength, temperature resistance, wear resistance, and reduced warping

TPU - flexible, impact and chemically resistant

Other - iglide®, Koltron G1, Addbor N2, OLIVE…

We tightly control internal structures along with multi-material printing to optimize strength and load-bearing performance. Complex geometries and integrated assemblies are no problem—our technology and experience make it seamless.

Post-processing options include sanding, smoothing, and painting to refine appearance and surface quality.

Whether you're after quick prototypes or production-grade parts, our FDM 3D printing services deliver precision, reliability, and value.

For a full list of materials and colors or to discuss your specific project, please contact us!

Polish it

We offer a wide range of part finishing services to enhance functionality, durability, and appearance—tailored to the material and end use of each part.

Surface Preparation & Cleaning

Sandblasting - creates uniform matte textures or prepares surfaces for coating

Pickling - removes oxides and scale from metal surfaces, commonly used for stainless steel to restore corrosion resistance

Tumbling - smooths and deburrs parts in batches for a clean, uniform finish

Mechanical Finishing

Grinding - precision surface and cylindrical grinding for tight tolerances and smooth finishes

Polishing - high-gloss or satin finishes for both aesthetic and functional purposes

Coating & Protection

Anodizing - corrosion and wear resistance for aluminum parts, available in multiple colors

Powder Coating - durable, protective coating with excellent adhesion and a range of colors and textures

Painting & Surface Dyeing - custom colors and markings for branding, visibility, or aesthetics

Thermal & Chemical Treatment

Heat Treating - enhances material properties such as hardness, strength, and wear resistance

Vapor Smoothing (for plastics) - chemically smooths and seals 3D-printed surfaces for improved finish and strength

Guarantee it

We offer a comprehensive suite of metrology solutions for high-accuracy inspection, alignment, and verification, whether in the shop or on-site.

Capabilities Include:

Portable Wide-Area Measurement (Probing/Scanning)

Accurate large-part and assembly inspection with a reach of up to 35 feet per measurement. Stitching available for extended measurement volumes.Machine-Mounted Probes

In-process measurement and part alignment directly on machining equipment to ensure repeatability and precision.Profilometer

Surface finish inspection for quantifying roughness, waviness, and texture on machined or printed parts.Laser & Structured Light Scanning

High-resolution 3D capture for inspection and documentation of complex geometries.Manual Precision Tools

Calibrated micrometers, calipers, bore gauges, indicators, height gauges, and more for fast and reliable dimensional checks.GD&T & Tolerance Analysis

Full geometric dimensioning and tolerancing inspections per engineering specs.First Article Inspection (FAI)

Thorough documentation and verification of initial production runs.

Repair it

We provide reliable maintenance support both on-site and off-site to keep your equipment running at peak performance. Our team is available during standard hours—and can work weekends, nights, or early mornings to minimize downtime and disruption.

Services Include:

Electrical Diagnostics & Repair - troubleshooting and repairing control systems, wiring, sensors, motors, and drives

Mechanical Repairs - bearings, gears, seals, actuators, fasteners, and general mechanical hardware

Machine Alignments - precision alignment of machines and assemblies for proper operation and reduced wear

Hydraulic & Pneumatic Systems -inspection, leak repair, and component replacement

Full Equipment Rebuilds — disassembly, inspection, and reassembly of machines to restore like-new function

Part Replacement & Retrofit — sourcing, fabricating, and installing replacement or upgraded components

Die Grinding & Repair - die maintenance to restore precision and extend tool life

Preventative Maintenance - scheduled service to avoid breakdowns and extend machine life

Emergency Breakdown Response - fast reaction time to unplanned failures and urgent issues

Trusted By