Case Studies

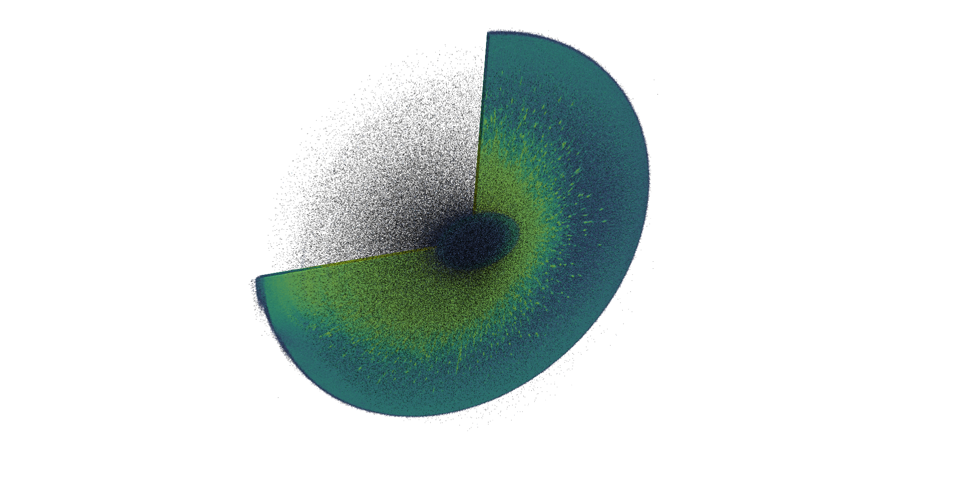

High-Fidelity Laser–Plasma Simulation

Contracted by the United States Air Force Research Laboratory, to deliver a simulation and analysis effort for developing high-fidelity models of ultrafast laser–matter interactions to better understand how energy is deposited and transported in extreme conditions. Our work paired the underlying physics (ionization dynamics and resulting instabilities) with practical computational engineering to run large-domain, high-resolution simulations that informed experimental interpretation and next-step design.

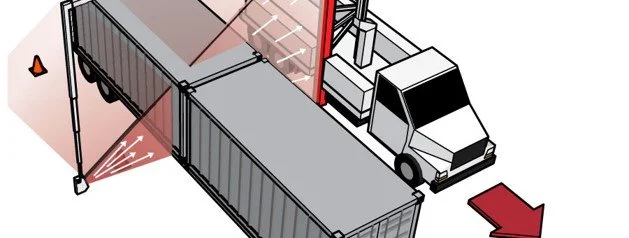

Detection of Nuclear Materials

Contracted by the U.S. Defense Threat Reduction Agency (DTRA) in collaboration with The Ohio State University, to produce a detection device concept intended to identify nuclear materials in occluded environments (e.g., behind vehicle and cargo barriers). The work combined the underlying measurement science, detecting and differentiating material signatures through intervening shielding, with practical engineering to translate that science into a usable, field-oriented screening device.

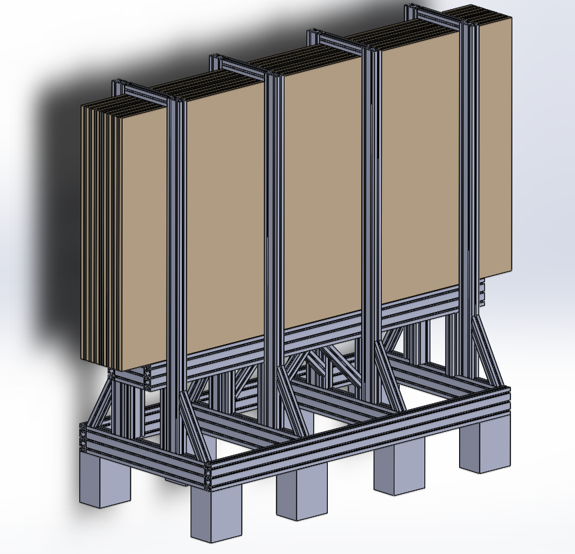

Contracted by the United States Air Force to support a high-energy laser research program, we developed practical radiation shielding estimates and translated those findings into a build-ready shielding solution. Using measured x-ray spectra, dose projections across expected shot rates, and attenuation data to size lead shielding, we designed a modular mobile lead-wall system, including structural layout, stability considerations, and a detailed materials/cut list, to create a safe “shadow zone” for personnel while preserving efficient lab workflow.

Radiation Shielding & Mobile Lead-Wall Design

Past Projects

Raw Material Roll Loading Lift Cart

Crocodile Cloth’s production facility came to Klim with a bottleneck: raw material rolls weighing roughly 100–150 lbs needed to be loaded onto spool holders about three feet off the ground. Their workaround was relying on physically strong operators to lift and position the rolls, an approach that limited hiring flexibility as they prepared to add a second shift.

Klim designed and built an automated rolling lift cart that fits between spool stations and lets operators roll a new material roll into position quickly and safely, then lift and load it onto the spool holder with minimal effort. The result was a faster reload process, reduced downtime, and thousands saved each week in regained production time. From design through approval and manufacturing, the full project was completed in four weeks.

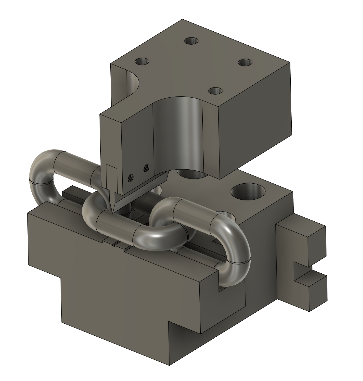

High-Throughput Chain Cutting Tooling

Columbus Design and Manufacturing, a high-volume welding and fabrication operation, came to Klim with a challenge: they needed tooling that could cut 10–15 chain links per minute. At the time, meeting the contract required three dedicated employees angle-grinding chain links all day for roughly two months each year.

After an on-site inspection, Klim identified an opportunity to repurpose underutilized equipment already in the facility rather than introduce an entirely new machine. We designed and built a tooling package that integrated directly with the customer’s existing equipment, increasing throughput to approximately 80–120 links per minute. The system was engineered around readily available components to simplify maintenance and ensure long-term reliability.

The result reduced labor requirements by two people and shortened the annual production time from two months to less than two weeks. Built in 2021, the tool has processed nearly two million links, with the cutting blade as the only wear component replaced to date. Total lead time from design through delivery was three weeks.

Autoclave Capacity Upgrade with Shield Stacking Carts

High Com, a manufacturer of body armor and first responder gear, relied on a process that applied vacuum to only six parts at a time during an autoclave step. While Klim was already supporting fabrication on another component, we identified that the existing workflow would require purchasing 6–10 additional ovens and vacuum carts to meet growing production demand. Klim proposed a more efficient approach and designed a shield stacking cart system that dramatically increased autoclave throughput, boosting process capacity by approximately 18× while avoiding major capital equipment purchases. We designed, fabricated, and delivered the stacking carts in three weeks, and they remain in active use today.

Rapid-Response 3D Printed Shipping Clips

3Bar Biologics faced an urgent logistics risk when a critical metal shipping clip was projected to run out within about two weeks, threatening delayed deliveries. Klim received the challenge on a Thursday, iterated 15 design concepts, and prototyped and presented the two best options by Friday. After approval, we immediately ramped production and delivered 1,500 3D-printed clips by the following Tuesday morning.

Roughly a month later, 3Bar placed a follow-on order for 17,000 clips. Klim delivered 2,000 within two days and the remaining 15,000 within ten days. The rapid design-to-production approach kept shipments moving and avoided the time and cost of rush injection molding, especially when no suppliers were willing to take the job on the required timeline.

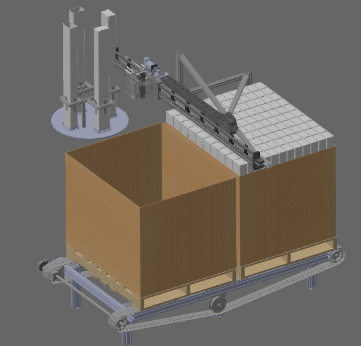

Lid-Feed Automation & Robotic Gantry Design

Crocodile Cloth’s packaging line consumes rectangular lids and was originally designed for manual loading, 20 banded lids at a time into a 160-lid magazine. To reduce labor, minimize downtime, and unlock the ability to source lids from multiple suppliers, Klim was asked to evaluate solutions capable of feeding the line unattended for an 8-hour shift. After initial discussions comparing options such as vibrating bowl feeders and other strategies, Klim was selected to design an automated process, custom packaging, and a robotic gantry system to reliably supply lids to the line. The final design met cost and production-rate constraints while building in room to scale for future production lines, and it is currently under customer review for fabrication. Total lead time was 4 weeks.